Gas Distribution Systems

Fully Assembled and Tested Gas Distribution Panels for Industrial Applications

Gas distribution systems must safely and effectively deliver gases from a high-pressure source to the end process at the pressure and flow rate required by each application. When system operation is not intuitive, when leaks are present, or when gas panels are difficult to service, however, problems can arise.

- Overlooked leaks of costly gases can reduce your profitability

- Leaks of utility gases can threaten process efficiency and raise operating costs

- Many leak types can also create safety hazards for your team members

- Gas delivery system issues can lead to process interruption and unplanned downtime

Often, industrial facilities do not have pressure reduction expertise or resources to effectively address these issues in their gas distribution systems.

See how our advisors help small teams optimize and better manage expansive gas distribution systems through our gas distribution program.

Swagelok® Gas Distribution Systems

Whether you need a standard solution or custom arrangement, we can design and assemble a gas delivery system that is right for you. Our standard gas delivery panels come fully assembled and tested. They are easy to order from our application guide as single part numbers, minimizing the time your engineers spend on specification and procurement of new systems. They are also highly configurable—we can add features or make modifications as needed to suit your requirements.

We design Swagelok gas distribution systems based on best practices. Our modular panels feature minimal threaded connections to reduce potential leak points, and they are intuitively labeled to promote safe, simple use and maintenance. All our gas distribution systems are backed by the Swagelok Limited Lifetime Warranty.

Hear our engineers talk about the different Swagelok-designed gas distribution subsystems we offer and the benefits they can create for you.

Choose From Modular Gas Distribution Subsystems

Swagelok gas distribution systems are built around one or a series of pressure regulation steps, and may include four subsystems:

- Swagelok® source inlet (SSI)

- Swagelok® gas panel (SGP)

- Swagelok® changeover (SCO)

- Swagelok® point-of-use (SPU)

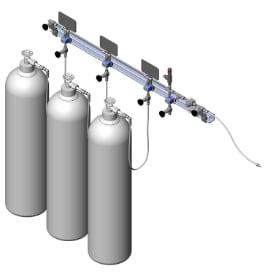

Swagelok® Source Inlet (SSI)

The source inlet establishes a connection between the high-pressure gas source and the distribution system. It is important the inlet is built with appropriate cylinder connections; hoses; tubing; filters; and vent, purge, and relief functions to ensure that gas can be safely fed into the primary gas pressure control or automatic changeover.

For a single gas cylinder, the assembly can be as simple as a hose and connector, while multiple cylinders may require a manifold incorporating many hoses and valves.

We offer:

- Highly configurable options to purge or vent gases when changing bottles, always ensuring operator safety

- Available option to vent individual lines to maximize uptime

How Our Local Advisors Can Help

It is easy to assume the source inlet will come standard with a new gas panel and will use the correct cylinder connector, but this is not always the case. Our advisors will ensure all componentry is included and correctly specified with minimal connection points, hoses that do not drop to the ground, and properly supported components. Additionally, we can advise when certain gases may require the use of special hoses.

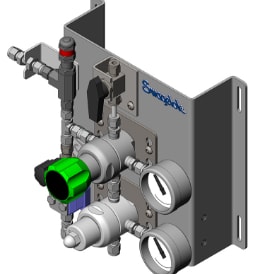

Swagelok® Gas Panel (SGP)

As the primary gas pressure control, the SGP completes the first pressure reduction of the source gas and ensures it is delivered at the correct flow rate to the next stage of the system. Pressure reduction is accomplished in either one stage with a single pressure regulator or two stages through a dual pressure regulator arrangement.

We offer:

- Modular panels that are easy to service as any part can be detached via a Swagelok connection, so the panel never needs to be removed

- Options implemented around the regulator and valves for color-coding if required for your site

How Our Local Advisors Can Help

Pinpointing correct inlet and delivery pressures can be difficult—our advisors will clearly explain considerations for different media. We can also help you understand where a two-stage regulator is required—many customers are surprised to learn most bottles do not require a twin-stage solution.

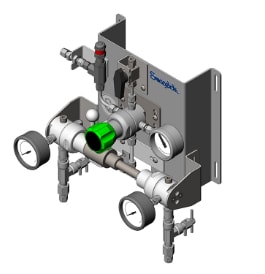

Swagelok® Changeover (SCO)

The automatic changeover system seamlessly switches from one gas source to another to ensure an uninterrupted supply. This is accomplished through staggered set points of two pressure regulators, allowing the system to continue to operate as the primary gas source is changed. Our changeover station allows for customer-specified changeover set points to help reduce wasted gas left in cylinders.

We offer:

- More assurance the changeover point remains constant

- Optional line regulation if your system incorporates a point of use regulator downstream—this can eliminate the additional cost of a regulator on the SCO

- Flexibility to set changeover pressure to your specification

How Our Local Advisors Can Help

Automatic changeover systems are widely used but often not well understood. Additionally, a “one size-fits-all” solution tends to be applied to many different systems where parameters and needs may vary. We can help your team better understand system functionality to take the uncertainty out of operation, troubleshooting, and maintenance.

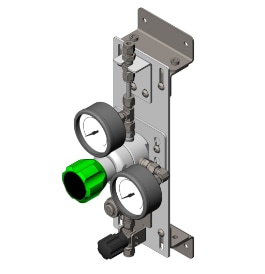

Swagelok® Point-of-Use (SPU)

The point-of-use provides the critical last stage of pressure control prior to the gas being used. These are often the least complex of the four main subsystems, typically having a pressure regulator, gauge, and isolation valve. Point-of-use systems offer a convenient and accurate method of adjusting pressure to meet test bench or equipment needs.

We offer:

- Standardization and consistent operation at the point-of-use

- Top-to-bottom or bottom-to-top flow to meet your setup needs

- Flat plate, bottom mount, top mount, and wall mount options

- Compact design

How Our Local Advisors Can Help

We can show you hidden savings, like how a single-stage SGP can be used to minimize cost where varying line pressure between the SGP and SPU is acceptable. All Swagelok® subsystems are highly configurable to your requirements, and our advisors will help you select the best components for the job and ensure the appropriate mounting option that minimizes the potential for damage to occur.

Additional Support for Gas Distribution Systems

In addition to helping you achieve your gas distribution goals by building standardized, highly configurable gas delivery solutions, we also offer Swagelok® gas distribution evaluation and advisory services .These services are delivered by Swagelok-certified gas distribution advisors who help you improve the reliability of gas distribution systems by analyzing your existing operations and recommending adjustments to improve system performance. They can help you:

- Protect the well-being of system operators and employees

- Improve uptime, process accuracy, and process repeatability

- Reduce costs by minimizing leakage and unplanned maintenance

- Focus your time and resources where they are needed most

We also offer local after-sales-support for our gas distribution systems to help you keep your systems operating as expected. Find out how our team can support you with training, inventory management, regular system evaluations, and comprehensive asset monitoring and management services.